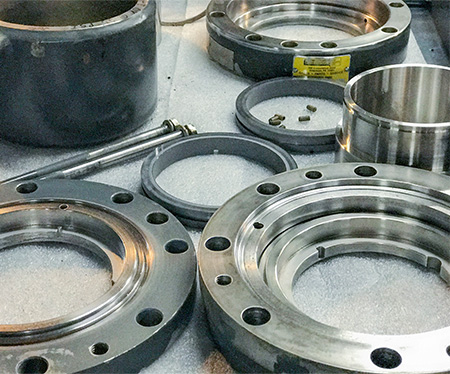

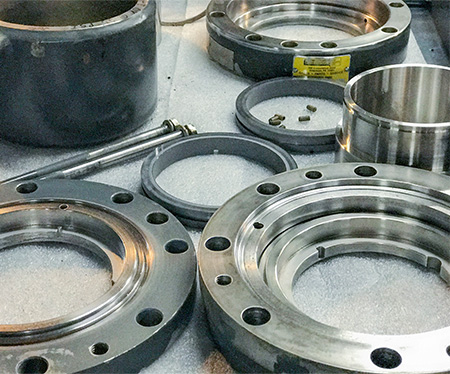

AES CDSA disassembled and ready for quoting.

GET HIGH-QUALITY MECHANICAL SEAL REPAIR FOR ALL BRANDS FROM RELIABLE EXPERTS

We provide expert Mechanical Seal Repair of all major brands, including John Crane®, Flowserve®, Burgmann®, and more. With locations in Gonzales, LA, and Williston, VT, we are the reliable, convenient single source repair for all styles of mechanical seals.

Our comprehensive library of manufactured design solutions addresses applications in the field and pump-specific challenges providing upgrades and replacement seals manufactured to perform better and last longer.

REQUEST A QUOTEOEM Mechanical Seal Repair

Hofman Seals experienced maintenance and repair technicians have worked with mechanical seals from the world’s largest pump and seal manufacturers, including John Crane® and Flowserve®. Below is just a sampling of the many manufacturers and styles that we have repaired. If your seal isn’t listed, just click “Request A Quote” to send us a message.

John Crane ® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following John Crane® mechanical seal models.

- Type 5615 Single and 5625 Dual Bellows Cartridge Seals

- Type 604, 606, and 609 High Temp Bellows Seals

- Type 670, 676, and 680 Low Temp Bellows Seals

- Type 8 O-ring Pusher Rotary and Cartridge Seals

- Type 9 Multi-spring Rotary and Cartridge Seals

- Don’t see your seal? Click “Request a Quote” to send us the details (including a picture!)

Eagle Burgmann® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following Eagle Burgmann® mechanical seal models.

Cartex Single Cartridge Seal

- Cartex Dual Cartridge Seal

- Burgmann MBS682 API 682-Compliant Mechanical Seals

- Burgmann M Series Rotary Seal

- Don’t see your seal? Click “Request a Quote” to send us the details (including a picture!)

Flowserve® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following Flowserve® mechanical seal models.

- BRC and BX Series API 682-Compliant Cartridge Seals

- ISC2 Series Cartridge Seals

- CRO, QB, and RA Pusher Seal Designs

- VRA and other Mixer Seal Designs

- Don’t see your seal? Click “Request a Quote” to send us the details (including a picture!)

AES Seal® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following AES Seal® mechanical seal models.

- CURC, CRCO, CURE Single Cartridge Seals

- CSM Single Mixer Cartridge Seals

- CDSA Dual Cartridge Seals

- DMSF and DMSC Dual Monolithic Cartridge Seals

- Don’t see your seal? Click “Request a Quote” to send us the details (including a picture!)

Chesterton® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following Chesterton® mechanical seal models.

- Chesterton 180, 155, and 186 Single Cartridge Seals

- Chesterton 280, 255, and 286 Dual Cartridge Seals

- Chesterton 886HT Bellows Cartridge Seal

- Don’t see your seal? Click “Request a Quote” to send us the details (including a picture!)

OEM® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following OEM Mixer seal models.

- Chemineer®

- De Dietrich®

- Ekato®

- Gyroclean®

- Lightnin®

- Pfaudler®

- Philadelphia®

- Ross®

- Don’t see your pump? Click “Request a Quote” to send us the details.

OUR MECHANICAL SEAL REPRAIR PROCESS

Hofman Seals experienced maintenance and repair technicians have worked with mechanical seals from the world’s largest pump and seal manufacturers, including John Crane® and Flowserve®. Below is just a sampling of the many manufacturers and styles that we have repaired. If your seal isn’t listed, just click “Request A Quote” to send us a message.

Cleaning, Evaluation

- Careful disassembly.

- Examination of components for wear and damage.

Estimating, Analysis

- Seal failure analysis is communicated to the customer, including recommendations for troubleshooting operating conditions to improve seal life.

- Estimate options are supplied for repair of the current seal to like-new condition and for an exchange to a Rolon Seal seal.

Custom Manufacturing

- Reverse engineering of necessary components.

- Machining capabilities at both VT and LA locations.

- Repair work done in-house for quick response

Testing, Assembly

- Quality inspection and pressure-testing to diagnose possible leak paths.

- All seals – new or repaired – go through a detailed assembly checklist to ensure sealing integrity.

Customer Service

- Application Engineering support.

- On-site service options.

- Personal communication throughout the entire repair process.

OEM® Mechanical Seal Repair

Hofman Seals capabilities include maintenance and repair services for the following OEM Mixer seal models.

- Chemineer®

- De Dietrich®

- Ekato®

- Gyroclean®

- Lightnin®

- Pfaudler®

- Philadelphia®

- Ross®

- Don’t see your pump? Click “Request a Quote” to send us the details.

Mechanical Seal Repair Kits

Hofman Seals offers repair kits for on-site seal repair. These kits are specific to your Rolon seal cartridge and are a great way to have parts on hand for an emergency situation. All items in the kit are packaged and labeled to ensure efficient change-out.

OEM Mechanical Seal Exchange Program

Hofman Seals offers various competitor seal repair and exchange programs. Contact us today to discuss your specific needs.

Mixer Seal Repair

Every mixer, agitator, and reactor model is distinctive and engineered for specific applications. When repairing a mixer seal,Rolonseals evaluates the conditions in which the seal operates. This evaluation ensures we are repairing your seal to your parameters.

Reverse Engineering

Sometimes a failed seal is no longer a candidate for repair. Hofman Seals provides straightforward solutions from our comprehensive seal lines or upgraded options designed for your unique operating environment.